-

Musk makes Davos debut with promise of robots for all

Musk makes Davos debut with promise of robots for all

-

Track star Sydney McLaughlin-Levrone announces pregnancy

-

NYC sues to block Dr. Phil-fronted police documentary

NYC sues to block Dr. Phil-fronted police documentary

-

Basking in Oscar nod, Russian videographer ready for Hollywood

-

WTO chief slams rise of trade protectionism

WTO chief slams rise of trade protectionism

-

Sri Lanka seal 19-run win over England in opening ODI

-

Germany expels Russian alleged spy handler, Moscow vows response

Germany expels Russian alleged spy handler, Moscow vows response

-

Casemiro to leave Man Utd at end of season

-

Frank says troubled Spurs 'going in right direction'

Frank says troubled Spurs 'going in right direction'

-

Springboks to meet All Blacks in USA for first time

-

Men's fashion turns to embroidery as guys want 'something different’

Men's fashion turns to embroidery as guys want 'something different’

-

In fiery Davos speech, Zelensky blasts EU, says US 'security guarantees' ready

-

Macron squares up to Trump in rebel shades at macho Davos gathering

Macron squares up to Trump in rebel shades at macho Davos gathering

-

Storms, heavy rain kill 14 across Afghanistan

-

Injuries force two changes in South Africa T20 World Cup squad

Injuries force two changes in South Africa T20 World Cup squad

-

In Greenland, locals fed up with deals done over their heads

-

Ex-marathon record holder Kosgei trades Kenya for Turkey at Olympics

Ex-marathon record holder Kosgei trades Kenya for Turkey at Olympics

-

Ariana snubbed and Chalamet supreme? Five Oscars takeaways

-

Germany summons Russian envoy, expels alleged spy handler

Germany summons Russian envoy, expels alleged spy handler

-

Wary Europeans huddle after Trump Greenland climbdown

-

Real Madrid stadium owners to face trial over concert noise

Real Madrid stadium owners to face trial over concert noise

-

'Sinners' breaks all-time Oscars record with 16 nominations

-

South Africa's Kruger park suffers 'devastating' damage from floods

South Africa's Kruger park suffers 'devastating' damage from floods

-

Molinari leads Dubai Desert Classic as McIlroy struggles

-

Ligue 1 leaders Lens still waiting for PSG title charge

Ligue 1 leaders Lens still waiting for PSG title charge

-

US touts 'New Gaza' filled with luxury real estate

-

Athens hit with several months of rain in one day: expert

Athens hit with several months of rain in one day: expert

-

Trump unveils Board of Peace, 'New Gaza' plans at Davos

-

Ubisoft shares plunge after big-bang restructuring announced

Ubisoft shares plunge after big-bang restructuring announced

-

Mendis' unbeaten 93 anchors Sri Lanka to 271-6 against England

-

Reeling Napoli face Juve after 'unacceptable' Champions League showing

Reeling Napoli face Juve after 'unacceptable' Champions League showing

-

Actor Liz Hurley in tears as accuses UK tabloid of 'monstrous' conduct

-

What we know about Trump's Greenland 'framework' deal

What we know about Trump's Greenland 'framework' deal

-

Trump launches 'Board of Peace' at Davos

-

Mercedes unveil 2026 F1 car for new 2026 rules

Mercedes unveil 2026 F1 car for new 2026 rules

-

Kitzbuehel's Hahnenkamm, the terrifying Super Bowl of skiing

-

'Oasis of stability': Madrid becomes luxury housing haven

'Oasis of stability': Madrid becomes luxury housing haven

-

Swiatek says packed tennis season makes it 'impossible' to switch off

-

Sloppy Osaka grinds past 'mad' Cirstea to stay alive at Australian Open

Sloppy Osaka grinds past 'mad' Cirstea to stay alive at Australian Open

-

Iran Guards chief says 'finger on trigger', warns US against 'miscalculations'

-

Imperious Sinner barrels into Australian Open round three

Imperious Sinner barrels into Australian Open round three

-

Storms, heavy rain kill 9 children across Afghanistan

-

Exhausted Wawrinka battles on in Melbourne farewell after five-set epic

Exhausted Wawrinka battles on in Melbourne farewell after five-set epic

-

'Too dangerous to go to hospital': a glimpse into Iran's protest crackdown

-

Bruised European allies wary after Trump's Greenland climbdown

Bruised European allies wary after Trump's Greenland climbdown

-

Australia mourns in candlelight for Bondi Beach shooting victims

-

Austrian ex-agent goes on trial in Russia spying case

Austrian ex-agent goes on trial in Russia spying case

-

Japan suspends restart of world's biggest nuclear plant

-

Djokovic, Swiatek roll into Melbourne third round, Keys defence alive

Djokovic, Swiatek roll into Melbourne third round, Keys defence alive

-

Trump to showcase 'Board of Peace' at Davos after Greenland u-turn

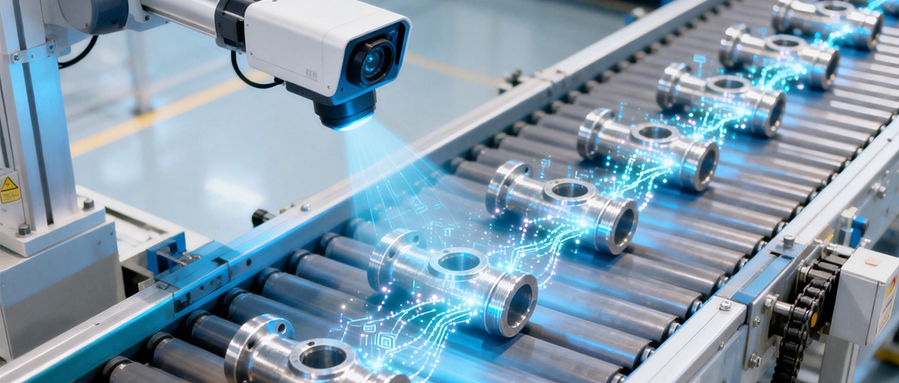

AI-Powered 100% Inspection: Redefining Quality Control in Smart Manufacturing

From Sampling to AI-Powered 100% Inspection

CHANTILLY, VIRGINIA / ACCESS Newswire / January 22, 2026 / For years, sampling inspection has been a reliable quality control method. By checking a portion of products, manufacturers have managed quality risk through statistics.

Today, that approach is being tested.

As factories scale up, product variants increase, and production speeds accelerate, quality expectations have shifted. It is no longer enough for products to be "acceptable." Manufacturers now expect consistency, stability, and traceability.

Quality inspection is no longer just a final check. It directly affects release decisions, rework, and on-time delivery. This leads to a critical question: Is sampling inspection still enough for modern manufacturing?

01 When Quality Relies on Sampling--The real risks

In fast-paced production environments, relying mainly on sampling creates clear challenges:

Quality issues are not continuously visible, and often appear too late

One missed defect can impact an entire batch, affecting delivery schedules

Production teams rely on manual experience to compensate, increasing uncertainty

Sampling itself is not the problem. The issue is that it was never meant to support end-to-end quality control in complex, high-speed production.

02 What "100% Inspection" Means Today

In practice, 100% inspection does not mean manually checking every detail of every product.

It means this: For defects or quality characteristics that can be automatically detected, every unit is inspected.

The difference is simple:

Sampling checks some products

100% inspection checks every product

As production volumes grow and takt times shorten, the cost of a single missed defect increases. As a result, per-unit inspection is increasingly becoming a practical requirement, especially in electronics, semiconductors, automotive components, and precision manufacturing.

03 Why AI Is Essential for 100% Inspection

Once inspection moves to full coverage, scale becomes the key challenge.

High-speed lines require constant decisions. Multiple product types and processes introduce changing defect patterns. Under these conditions, manual inspection and rule-based systems struggle to keep up.

This is where AI-based inspection becomes essential. Not because it is more advanced, but because it can learn, adapt, and operate continuously at scale.

The focus shifts from whether AI is needed to how it should be deployed to fit real production environments.

04 Making AI Inspection Work in Practice

InHand Networks has developed an AI quality inspection solution designed around production speed, reliability, and long-term operation. The goal is simple:Make per-unit inspection a dependable part of daily production.

On the production line

To avoid slowing production, inspection must match takt time. High-resolution cameras generate large data volumes, and relying on remote systems can create delays.

In this solution, the EC5550 Edge Computer is deployed directly on the production line. It processes camera data locally and performs defect detection in real time.

Key benefits include:

Up to 100 TOPS of AI performance for multi-camera inspection

Millisecond-level response times aligned with production speed

Industrial-grade reliability for continuous operation

With stable, on-site processing, inspection becomes part of the production flow rather than a bottleneck.

Turning inspection data into insight

Per-unit inspection creates value only if results are captured and used.

Inspection data is collected into on-premises systems or a private cloud, creating a continuous quality record. Each product's status, defect type, and timing can be traced.

By integrating with MES and QMS systems, recurring defects or abnormal trends trigger alerts automatically. Quality control moves from reactive checks to process-level control.

The role of the cloud

In this architecture, the cloud does not handle real-time inspection. Instead, it focuses on:

Cross-line and cross-factory quality analysis

Centralized AI model training and evaluation

Unified model updates

Even if the network is unstable, on-site inspection continues uninterrupted. The edge executes; the cloud improves.

05 What Changes with Per-Unit Inspection?

Moving from sampling to per-unit inspection is more than a technical upgrade. It reflects a shift toward greater certainty in quality management.

The value of AI is not that it appears smarter, but that it helps production run smoothly and predictably. When quality control is based on continuous, reliable decisions-rather than probability-it becomes a system that can support long-term manufacturing operations.

Learn more: https://www.inhand.com/en/products/ai-edge-computers/

About InHand Networks

InHand Networks is a leading IoT solutions provider founded in 2001, dedicated to driving digital transformation across industries and empowering customers to unlock their full potential and achieve accelerated growth.

We specialize in delivering industrial-grade connectivity solutions for diverse sectors, such as business networks, industrial IoT, digital energy, smart commerce, and mobility. Our comprehensive product portfolio and services cater to various applications worldwide, including smart manufacturing, smart grid, intelligent transportation, smart retail, etc. With a global footprint spanning over 60 countries, we serve customers in the United States, France, Germany, the United Kingdom, Italy, China, and beyond.

Learn more: www.inhand.com

Media Contact

Eleanor Chen

Marketing & Communications

[email protected]

SOURCE: InHand Networks

View the original press release on ACCESS Newswire

G.Stevens--AMWN